3D Contact Tutorial

This tutorial gives a short introduction to the setup of a simple 3D contact problem. The goal of this tutorial is to give an overview of the general workflow in 4C and to show how to create a working input file. It is neither intended to be an introduction to the theory of contact mechanics, nor demonstrate all possible optional settings for a given (contact) problem.

Introduction

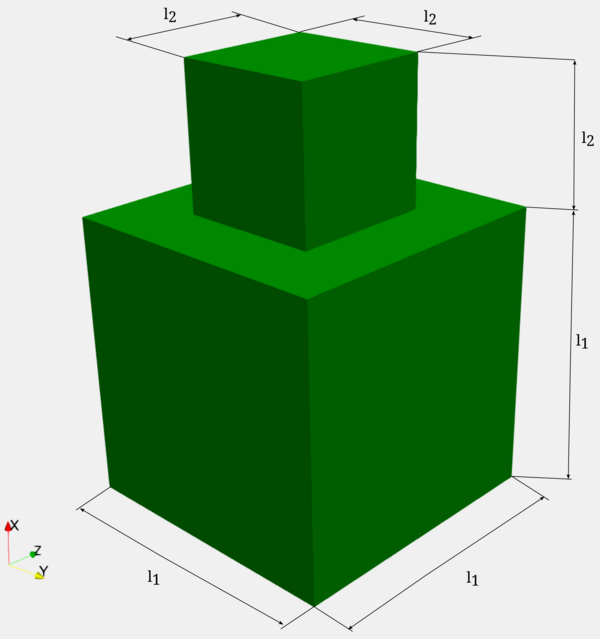

The analyzed problem setup contains two elastic cuboids of different dimensions, consisting of materials with different mechanical properties pressed onto each other. The geometry of the problem setup is shown in the subsequent figure

|

|---|

Geometrical setup of the contact test. |

with measures as listed in the table below

Quantity |

Length in (mm) |

|---|---|

\(l_1\) |

0.5 |

\(l_2\) |

1 |

The materials chosen in this tutorial are artificial. The material of the lower block is softer, represented by the elastic properties \( \text{E}_1 = 100 \) MPa, \( \nu_1 = 0.3\), while the upper block has the elastic properties \( \text{E}_2 = 4000 \) MPa, \( \nu_2 = 0.3\).

Preprocessing

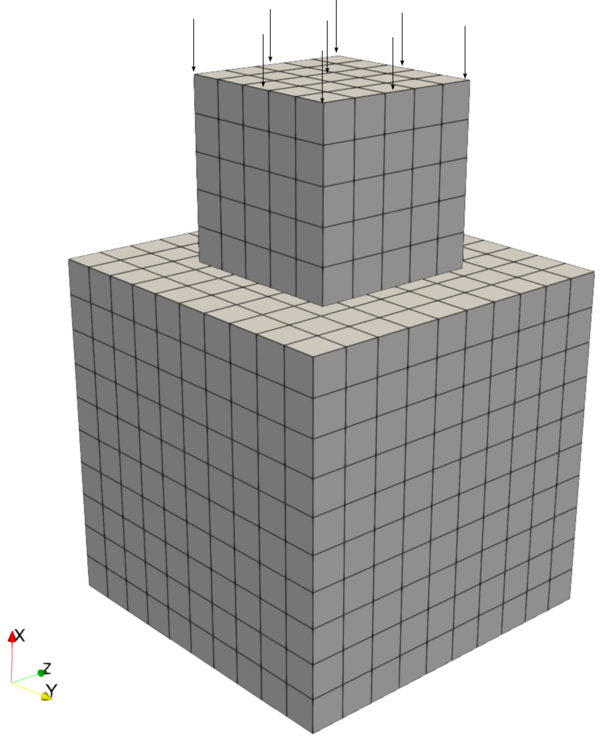

The mesh of the discretized problem setup used in this tutorial is shown in the figure below.

|

|---|

Mesh of the problem setup including arrows to visualize the displacement boundary condition that drives the deformation. |

The discretization of the upper and lower blocks does not coincide. Thus, we obtain non-matching discretizations at the contact interface as soon as the bodies get into contact due to the prescribed displacement.

Here is an interactive version of the mesh where you can explore the mesh on your own by rotating and zooming:

Working with 4C

Creation of a valid 4C input file

To simulate the described problem using 4C, a valid 4C input file is necessary.

A valid template input file for this problem is already provided with the file tutorial_contact_3d.4C.yaml.

Note

Consider using an IDE like VS Code or Clion to open the 4C input files.

These IDEs can be set up to use the JSON Schema file (4C_schema.json) provided by 4C.

This can be very helpful as it enables to display the documentation of the parameters, allows for auto completion, and shows the different options that can be set.

The file ending of the 4C input files is .4C.yaml.

Note

The documentation of the input parameters can also be very helpful to adapt the input files.

As this is still a solid mechanics problem, many definitions are similar to those in the solid mechanics tutorial. Thus, it is also recommended to perform this tutorial first. The main difference from a solid mechanics perspective is that we do not assume a quasi-static problem setup but account for the dynamics of the system.

STRUCTURAL DYNAMIC:

INT_STRATEGY: Standard

TIMESTEP: 1.0

NUMSTEP: 2

MAXTIME: 10.0

DYNAMICTYPE: GenAlpha

RESTARTEVERY: 10

TOLDISP: 1.0e-06

TOLRES: 1.0e-06

LINEAR_SOLVER: 1

Therefore, the time integration scheme is chosen to be Generalized-\(\alpha\) (DYNAMICTYPE: GenAlpha).

Note

The number of time steps NUMSTEP is set to 2 in the template file to keep the simulation time short for the CI/CD tests.

If you want to run the whole simulation, you have to change the parameter to at least NUMSTEP: 10.

Moreover, as it is a contact problem, additional contact related parameters must be defined. This is done with the subsequent sections

MORTAR COUPLING:

ALGORITHM: Mortar

LM_SHAPEFCN: Standard

CONTACT DYNAMIC:

STRATEGY: Penalty

PENALTYPARAM: 1.0e3

LINEAR_SOLVER: 1

In this tutorial, a segment-to-segment contact formulation, namely a mortar approach, is used for the contact interface discretization.

Therefore, the MORTAR COUPLING section has been added, and the ALGORITHM has been chosen as Mortar.

Furthermore, shape functions for the mortar discretization are chosen to be standard Lagrange shape functions (LM_SHAPEFCN: Standard).

In contact problems, additional constraints need to be fulfilled.

For normal contact without friction or adhesion effects, these are described by the following set of equations

where the first equation expresses that the gap \( g_\text{n} \), i.e., the distance between the two bodies, must be non-negative to avoid a penetration of the body. The second equation states that only compressive contact stresses \( p_\text{n} = \boldsymbol{n} \cdot \boldsymbol{\sigma} \cdot \boldsymbol{n} \) (Cauchy stress tensor: \(\boldsymbol{\sigma}\), local normal vector: \(\boldsymbol{n}\)) can be transferred. Remember that we excluded effects like adhesion in the beginning. Finally, the last equation states a compatibility condition, meaning that if the gap is zero, we have compressive stresses in the interface, and when the gap is larger than zero, i.e., the bodies are not in contact, the contact stress has to be zero. For more information on contact methods in general please refer to [1] and [2], while for mortar methods we refer to [3] and [4].

There are different possibilities to enforce such constraints within a numerical model.

In this tutorial, we will work with the Penalty and Lagrange multiplier methods.

The Lagrange multiplier method introduces new degrees of freedom, the Lagrange multipliers, to the numerical model.

In the converged state, the values of the Lagrange multipliers can be interpreted as the forces necessary to fulfill the constraints.

In contrast, the Penalty method by construction allows for a violation of the constraints but penalizes the constraint violation.

The penalty parameter is the relevant parameter to tune to which extent the constraints are violated.

This method can be viewed as a regularized variant of the Lagrange multiplier approach, where, in theory, the exact solution is recovered as the penalty parameters tend toward infinity.

Initially, this tutorial uses the Penalty method (STRATEGY: Penalty).

This constraint enforcement method requires a so-called penalty parameter, which is set to be 1.0e3.

On top of that, a linear solver must be defined (LINEAR_SOLVER: 1) for the contact problem.

The contact interface, i.e., the surfaces that might come into contact, must be defined. This is done with the following lines in the input file

DESIGN SURF MORTAR CONTACT CONDITIONS 3D:

- E: 1

ENTITY_TYPE: node_set_id

InterfaceID: 1

Side: Slave

- E: 2

ENTITY_TYPE: node_set_id

InterfaceID: 1

Side: Master

stating that a three-dimensional contact problem shall be solved.

Moreover, two surfaces are defined to be part of the contact interface with InterfaceID: 1, defining that the contact constraints shall be enforced for this pair of surfaces.

Additionaly, a distinction in Master and Slave is common in the contact community.

This is also done here by the parameter Side.

In contrast to the simpler approach of node-to-segment (NTS), the decision which side is Master and which is Slave is not that important.

Note

It is common practice to choose the side with the finer discretization as the slave side.

The execution of 4C and the post-processing work as described in the solid mechanics tutorial and are not repeated here.

Numerical analyses

Step 1

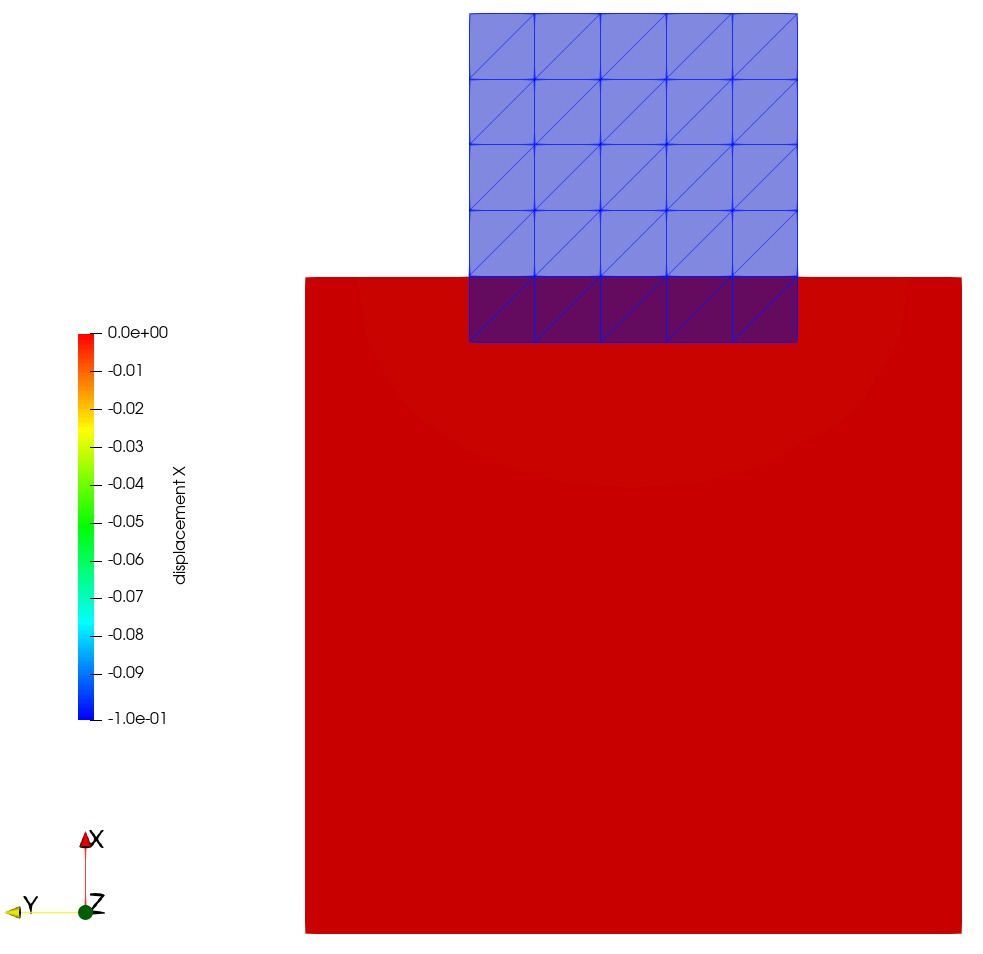

First, we want to analyze the properties of the penalty method for contact constraint enforcement. As described above, a penetration of the bodies is inherent to this method, as the penetration is penalized by adding a penalty term that scales with the penalty parameter. Thus, your task is to evaluate the influence of the penalty parameter on the simulation result.

Solution

The task is to play around with the values of the penalty parameter, i.e.,

CONTACT DYNAMIC:

STRATEGY: Penalty

PENALTYPARAM: 1.0e3 # vary this value here

and check how this affects the solution of your problem.

You will encounter the penetration of the bodies getting higher for lower penalty parameter values. For sufficiently small penalty parameters, the penetration of the bodies gets so high that the contact algorithm no longer detects that the surfaces are actually in contact, and the bodies freely penetrate each other.

For higher values of the penalty parameter, the penetration of the bodies gets smaller, as expected. However, a large penalty parameter also leads to a bad conditioning of the linear system. Thus, the linear solver will not solve if the penalty parameter gets too high.

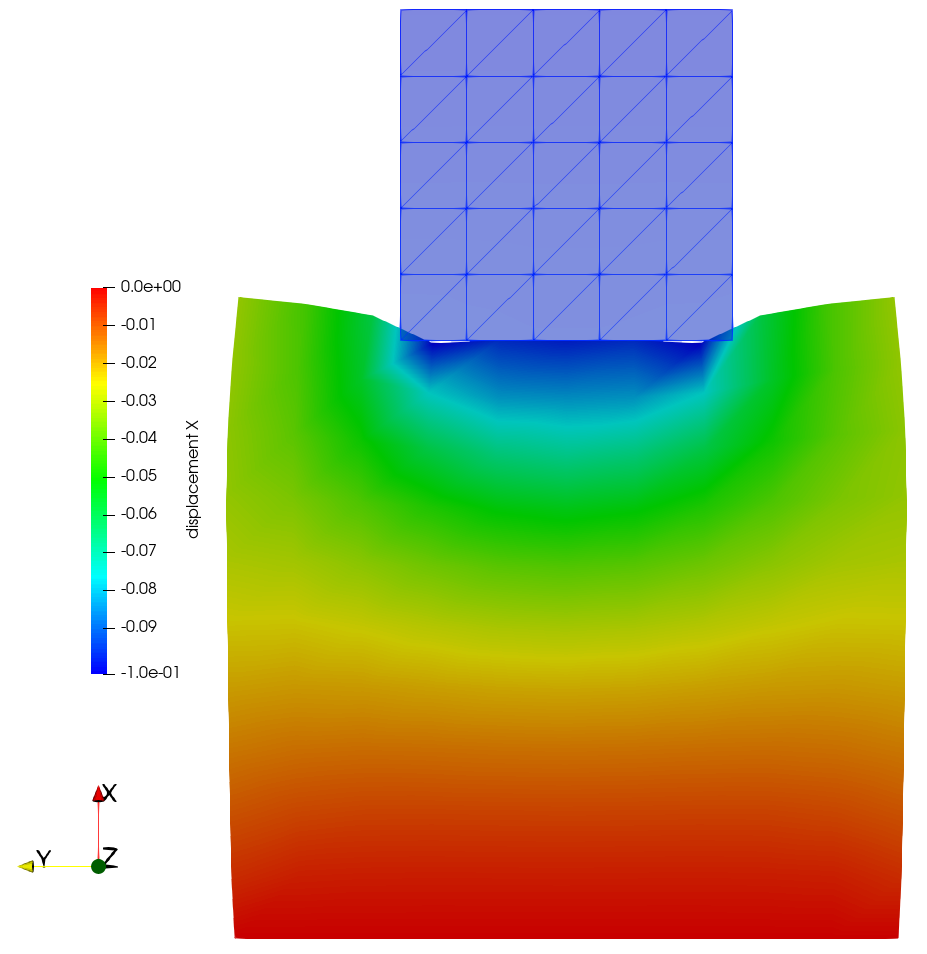

|

|

|

|---|

Displacement field solution for three different penalty paramters. Left: Penalty parameter so low, that penetration is so large that contact search is not successful any more. Middle: Small penalty parameter leading to significant penetration. Right: High penalty paramter resulting in only small penetrations.

Hint

To check if the bodies are still in contact you can either use ParaView and visualize, e.g., the deformation field.

As an alternative, you can also check the screen output for the following lines

Converged....Contact-Normal-Active-Set-Size = 49

**...........Number of Iterations = 3 < 50

where the output Contact-Normal-Active-Set-Size describes how many discrete nodes are actually in contact.

Thus, if no contact is found anymore, the number is 0.

Step 2

The penalty method is an established method, as it is easy to implement and often performs quite well, despite the obvious drawbacks you have encountered during the last couple of simulations.

Thus, we want to move your attention to an alternative constraint enforcement method that uses Lagrange multipliers.

To achieve that, you need to adapt the MORTAR COUPLING and CONTACT DYNAMIC sections of your input file as follows

MORTAR COUPLING:

ALGORITHM: Mortar

LM_SHAPEFCN: Dual

CONTACT DYNAMIC:

LINEAR_SOLVER: 1

STRATEGY: Lagrange

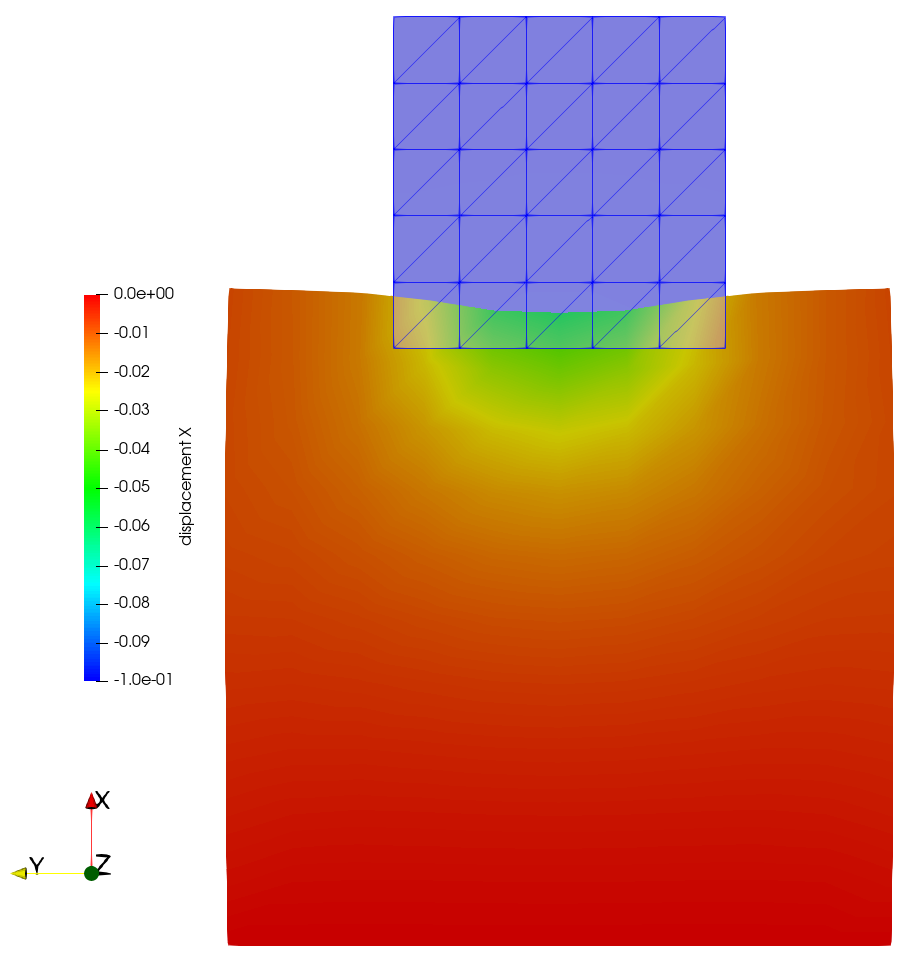

Solution

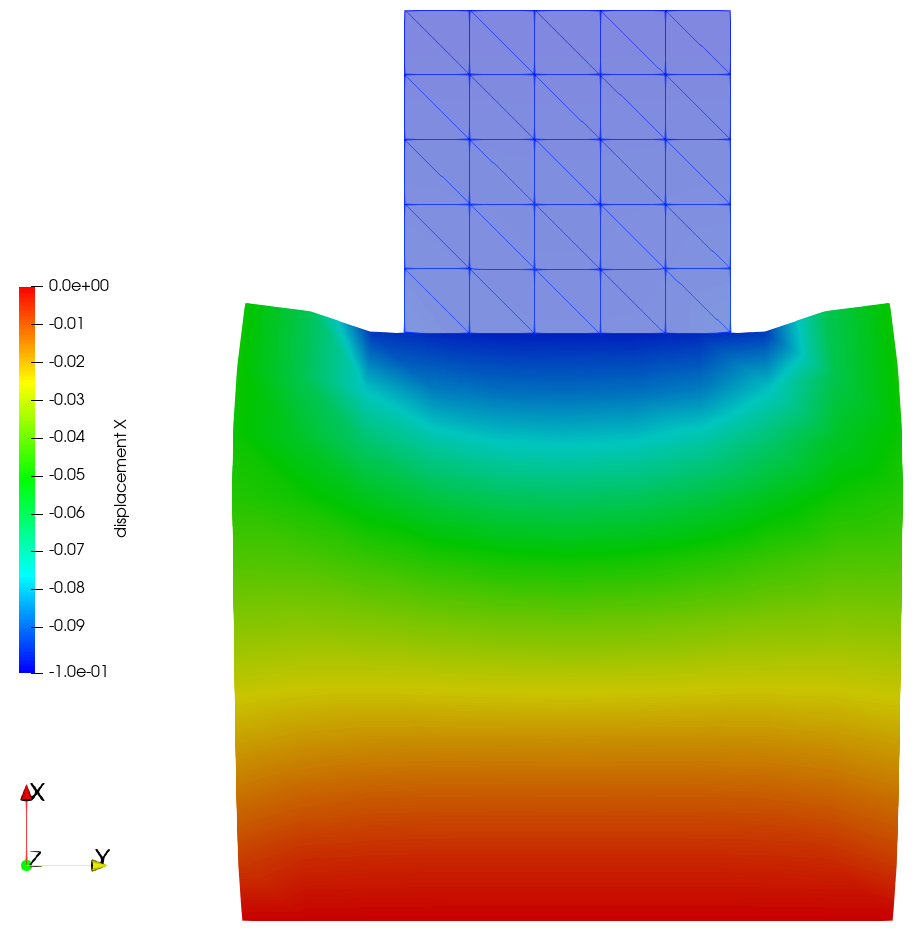

When you execute the simulation, you will see that the penetration of the bodies is gone (see figure below).

|

|---|

Displacement field solution for the Lagrange multiplier constraint enforcement method. |

This is because the constraint enforcement using the Lagrange multipliers is exact in a weak sense. However, this method comes with other challenges, e.g., a saddlepoint structure of the linear system that requires specialized linear solvers, especially for large systems when iterative solvers are needed. One possible remedy to this issue is using so-called dual shape functions (see the definition above), which enable a complete condensation of the Lagrange multipliers and thereby remove the saddlepoint structure of the linear system.